Hazardous substances stored and used in production or service processes may pose a significant threat not only to the environment, but also to people. Uncontrolled leakage from a pallet container or a barrel can contaminate the ground and cause an accident at work, e.g. an employee burns with acid or slips and breaks a limb. In order to minimize this risk, appropriately selected spill containment berm are used.

What are spill containment berms?

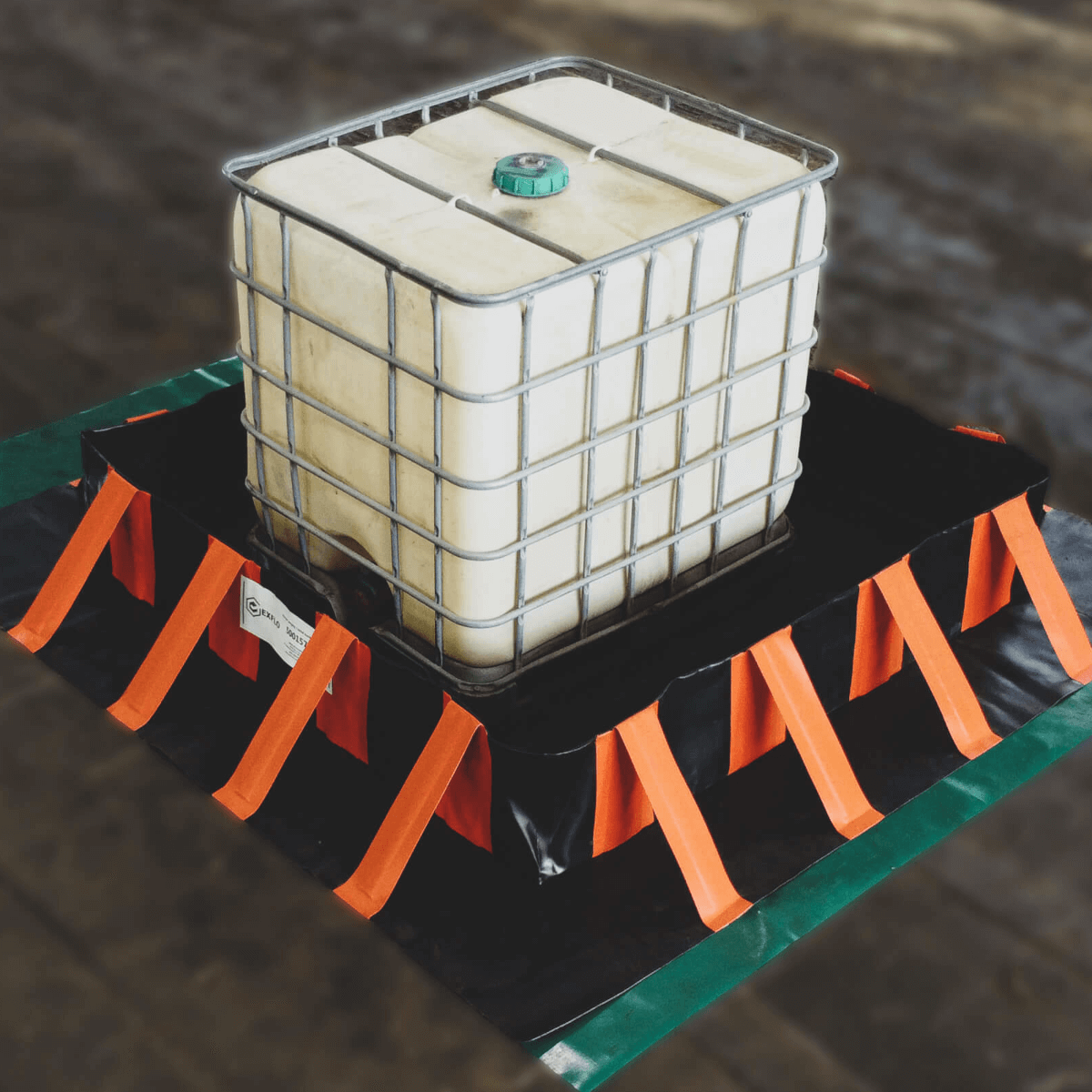

Spill containment berms are installations that collect substances coming out of leaky containers or barrels. They are used to protect surfaces and grounds against contamination, and also reduce the risk of accidents for people in close proximity to the stored materials.

Spill containment berms prevent the spread of potentially hazardous chemicals. They act as a barrier that stops liquid material from entering the external environment.

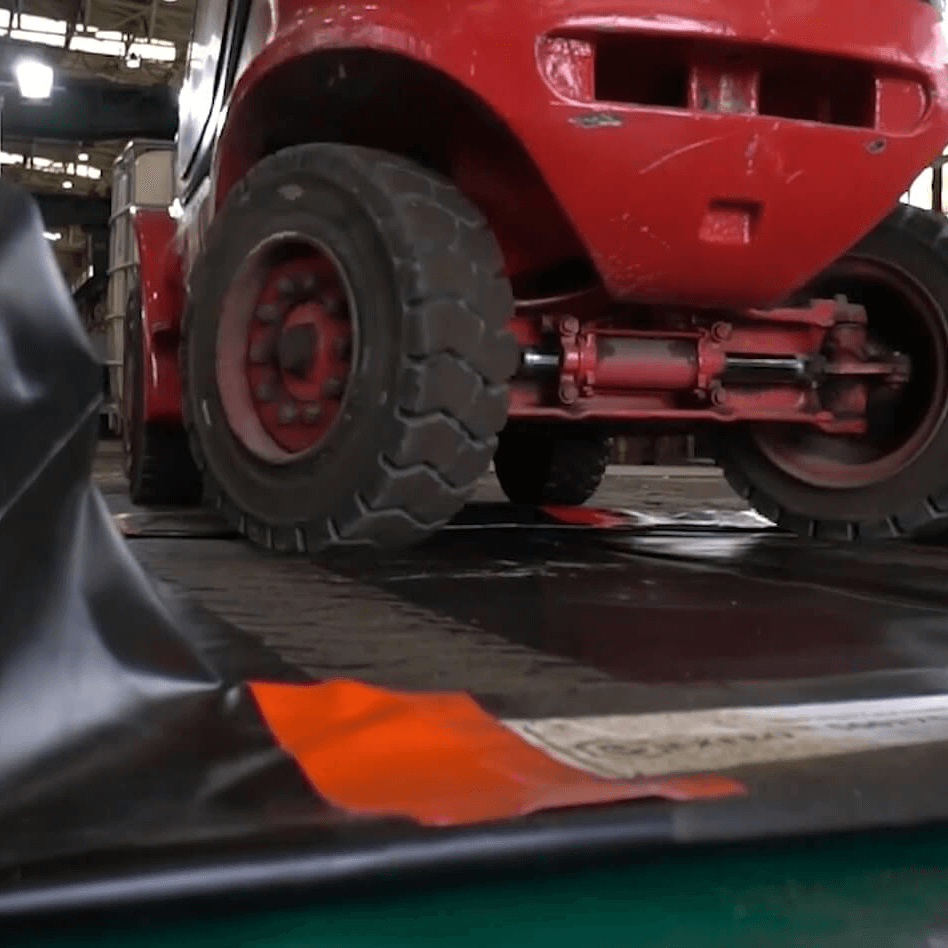

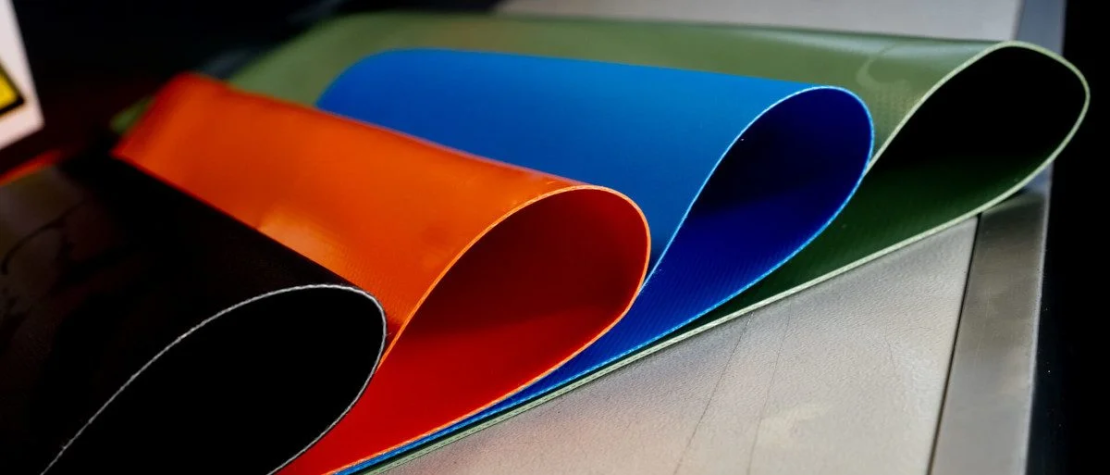

The berm is a tank made of durable and impermeable materials – Polish manufacturers offer on the market e.g. steel sump tubs as well as those made of special multi-layer, flexible and lightweight fabrics. Containers, barrels or canisters filled with liquid substances are placed inside the tank in case of leakage and uncontrolled leakage.