Spill containment berms – what should you pay attention to?

Storing hazardous substances in barrels or pallet containers may pose a real risk of sudden, uncontrolled leakage. The solution is escapement tanks, which increase safety in the event of such an event. In particular, the environment which is protected against the penetration of a dangerous substance or mixture into the ground or water, employees – against a possible accident and loss of health, as well as the employer himself – against the consequences of these events – both financial (compensation, penalties, disposal costs, etc. ) and legal. It is therefore worth taking the time to choose the right solution.

It’s an obligation to contain fluid spills

It is no secret that the law does not usually keep pace with progressive changes and practices. This was also the case with the definition and description of the sump tray function in Polish regulations. Baths were of course known and used, especially as collective protection of workers and the environment against contamination. However, it was not until 2020 that their legal definition appeared. According to the ordinance [1], a spill tray is a “spill-reducing solution”.

This short definition is very accurate, although it only appeared in the regulation in the context of liquid combustible waste. Limiting the risk of flooding, so that it does not entail further negative effects, e.g. a collision of forklifts on an oily floor, is also a proper and, in accordance with the provisions of the Labor Code, an obligatory activity of the Employer as part of ensuring safe working conditions.

Furthermore, it should be borne in mind that unloading and loading containers with hazardous substances is a process in which the risk of damage to the container and the leakage itself increases enormously. In order to limit the spillage of the substance, such an area should be properly prepared (e.g. it can be made of concrete, with directional drainage and a temporary tank) or equipped with a large-scale sump tray, adapted to the movement of forklifts and trucks in it.

Types of spill containment berms available on the market

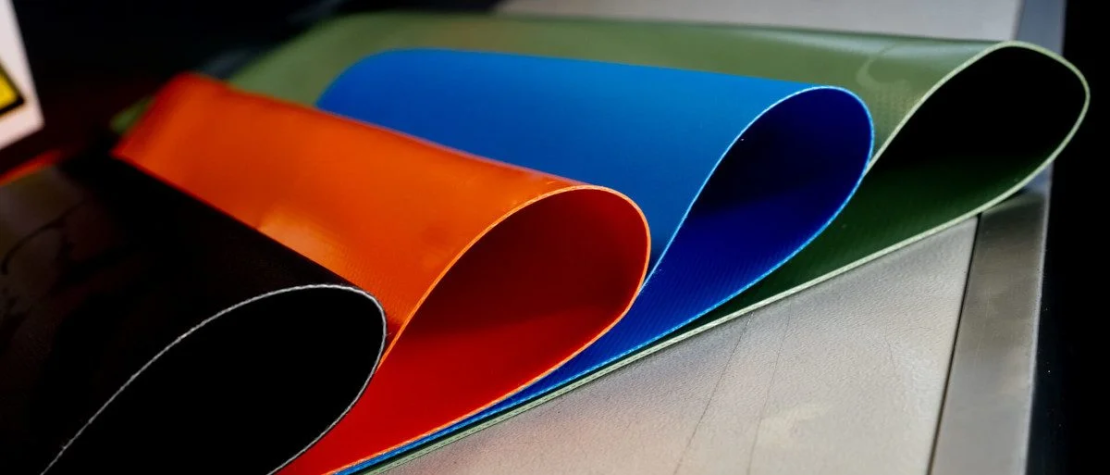

After entering the phrase “spill tanks” in the search engine, you will see a whole range of products made of various materials. Is it possible to use a tub made of stainless steel, polyethylene or made of “flexible” technical fabric for the storage of hazardous substances? Yes, because the law imposes the obligation to “limit the spill”, but allows you to choose the technology and material from which such a solution is to be made. Bathtubs can be made of various materials, which include, for example, Sump tubs can be made of materials such as:

- galvanized or painted steel,

- acid-resistant and stainless steel,

- hard materials: polyethylene,

- soft, flexible materials, incl. fabrics coated with polyvinyl chloride, polyurethane, etc.

The amount of material types, bath tub sizes and capacity (known as “uptake”) can give some people a headache. Buying an expensive but solid stainless steel bathtub may not be the best decision. The sump tray should first of all be tailored to the activities of a given company and the needs of end users (e.g. warehouse management), who should be involved in the process of choosing the final solution.

The selection of a suitable sump should be based on several factors that should be taken into account when making such a selection.

Safety data sheet

You should choose the same material of the bathtub, which is indicated in the card as the material of the tank for the indicated substance – if such information is provided there. If it is a flammable substance, the bathtub material should not be the source of the spark. Pay attention to the possibility of discharge of electric charges. In addition, the containers cannot stand on the same tub with substances that will create another chemical reaction that poses a threat to workers and the environment.

Capacity – uptake

A good practice will be to follow the above-mentioned regulation of the Ministry of Interior and Administration, which indicates the appropriate (net) capacity of the sump tray for combustible waste. These values are positively received by security experts and most often suggested as general guidelines:

- 25% of the total volume of stored substances or

- 110% of the capacity of the single largest package, unit container or portable tank – whichever is greater.

Active or passive storage

If liquid is frequently drawn from the tank containing the bathtub, especially in small amounts, tall bathtubs with a grate are better suited. When the tanks are mainly stored (passive storage), it is worth considering a bathtub for several or even several dozen containers. Many containers can be placed on special modular mesh floors or in flexible sump trays.

Attention! Regardless of the type of storage, the sump must not have a drain valve.

Logistics and functionality

Traditionally, solutions with a clearance, i.e. a place for forks for forklift operators, may also be convenient. On the other hand, soft plastic tubs, when folded, usually occupy a few percent of their capacity, which greatly facilitates their handling and transport, as well as storage, when the company changes its production profile.

Attention! In any case, transporting the container with the bathtub or on the bathtub by means of a forklift is extremely dangerous and forbidden. According to numerous industry discussions, it is a common practice of employees in the area of construction sites and warehouses.

Manufacturer, quality, trust, price

Before making a purchase decision, it is also worth checking the opinions about a given product and about the manufacturer / importer, and ask the staff about the details that interest us, especially in the context of safety data sheets and specific substances that can be stored over the bathtub. If we do not define our needs correctly and we do not define the minimum initial parameters for the solution sought, the price selection criterion may even reduce the level of security.

Increasing safety in the workplace should be the intention of every employer, especially when employees come into contact with substances that threaten their health and life. Despite the many ambiguities in national regulations, I encourage you to develop a set of good practices, raise the awareness of the team through hands-on training and search for the best solutions for your company.