2 Drum Spill Containment Berm

430,00€ 528,90€

- Dimension – 1,90 x 0,65 x 0,35 m

- Capacity – 410 l

- Shipping term – 14 working days

Hazardous substances stored and used in production processes, such as oils, acids or chemical compounds, pose a potential threat to the health of employees and the natural environment. Spill containment berm for two barrels is an effective protection against leakage and spillage of the stored substance.

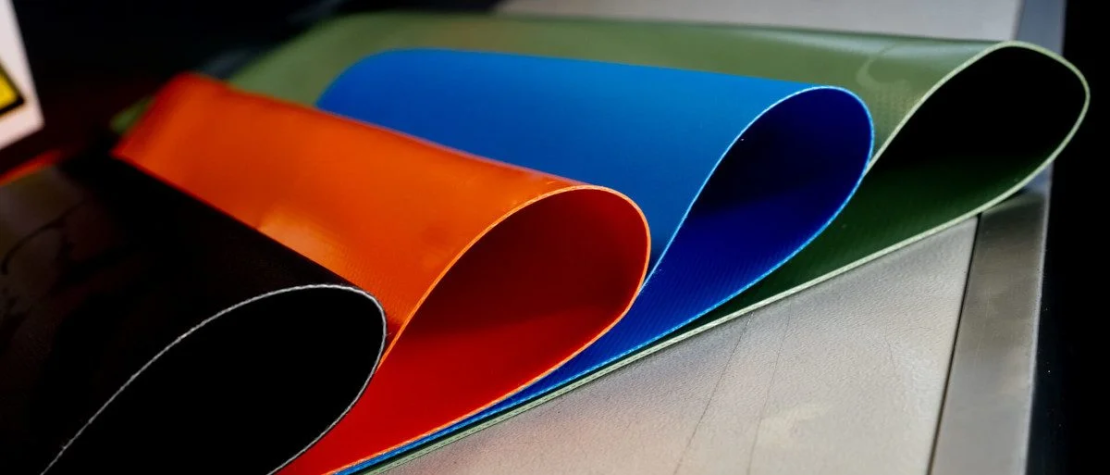

The spill containment berm is made of a special technical fabric coated with poly(ethylene-co-vinyl acetate), EVA for short, with a weight of 1365g/m². This guarantees very high resistance to mechanical damage and a number of chemical substances, such as acids or oils. All this allows us to provide a 7-year product warranty.

Hazardous substances stored and used in production processes may pose a significant threat not only to the environment, but also to people. Uncontrolled leakage may contaminate the ground and cause an accident in the workplace.

| Specific weight | 1365 g/m² |

| Fabric | EVA coated polyester – poly(ethylene vinyl acetate) |

| Colour | black |

| Cold resistance | -40°C |

| Heat resistance | +70°C |

| Breaking Strength: Warp | 730 kg / 5 cm |

| Breaking Strength: Weft: | 700 kg / 5 cm |

| Warranty | 7 years |

Spill containment berm resistance list

Questions & Answers

1. Is the spill containment berm resistant to such chemicals as e.g. diesel oil, glycol, ethanol or 32% hydrochloric acid?

Yes, the material is resistant to these types of substances. However, we suggest that you check the resistance list in the “Download” section before choosing the appropriate berm.

2. Should every chemical be stored in a spill containment berm?

Each hazardous chemical substance should be stockpiled or stored in containment to limit potential leakage. One of such solutions is a spill containment berm. Information whether the material is hazardous should be included in the safety data sheet of the stored substance (see warning pictograms). In addition to the category of the hazardous substance, it is worth considering whether a potential leak on the floor will cause an accident, e.g. slipping of a forklift, fall of an employee.

3. What is the process of cleaning the spill containment berm?

In the event of a substance leaking into the sump tub, the spill should be removed using the means recommended by the substance manufacturer and based on the applicable safety rules for this type of event. In practice, appropriately selected sorbents are often used.

4. Can the forklift be driven on the spill containment berm?

Yes – after removing the brackets and placing the wall, you can move a wheelchair or even a truck on the spill containment berm surface. The material in the EFB Plus version is sufficiently durable.

5. What is the containment capacity of the spill containment berms?

There are no specific regulations in Europe regarding the capacity of spill containment berms. The appropriate capacity of a spill containment berm would depend on the specific requirements and needs of the storage or production facility, as well as any relevant regulations and guidelines that may be in place.

In general, it is recommended to follow the guidelines provided by industry standards and regulations, such as those set by the European Chemicals Agency (ECHA) and the European Union (EU). The capacity of the spill containment berm should be based on the maximum volume of the largest container or tank that is being used or stored in the area, and should be sufficient to contain any spills or leaks

6. What is the difference between Standard and Compact version?

The Standard version has separate, slide-in supports, while the Compact version has built-in supports. The Standard berm is easier to use, because it is lighter, so it is easier to “maneuver” it – to move it, unfold it, fold it.